Biogas

We are part of the global biogas supply chain and export engineering services, equipment and process modules....

Read More

Gas processing

GPE designs and supplies gas cleaning, Purification and conditioning systems which meet stringent process..

Read More

Dehydration

GPE supplies custom designed, skid mounted Dehydration packages for hydrocarbons as well as other gases...

Read More

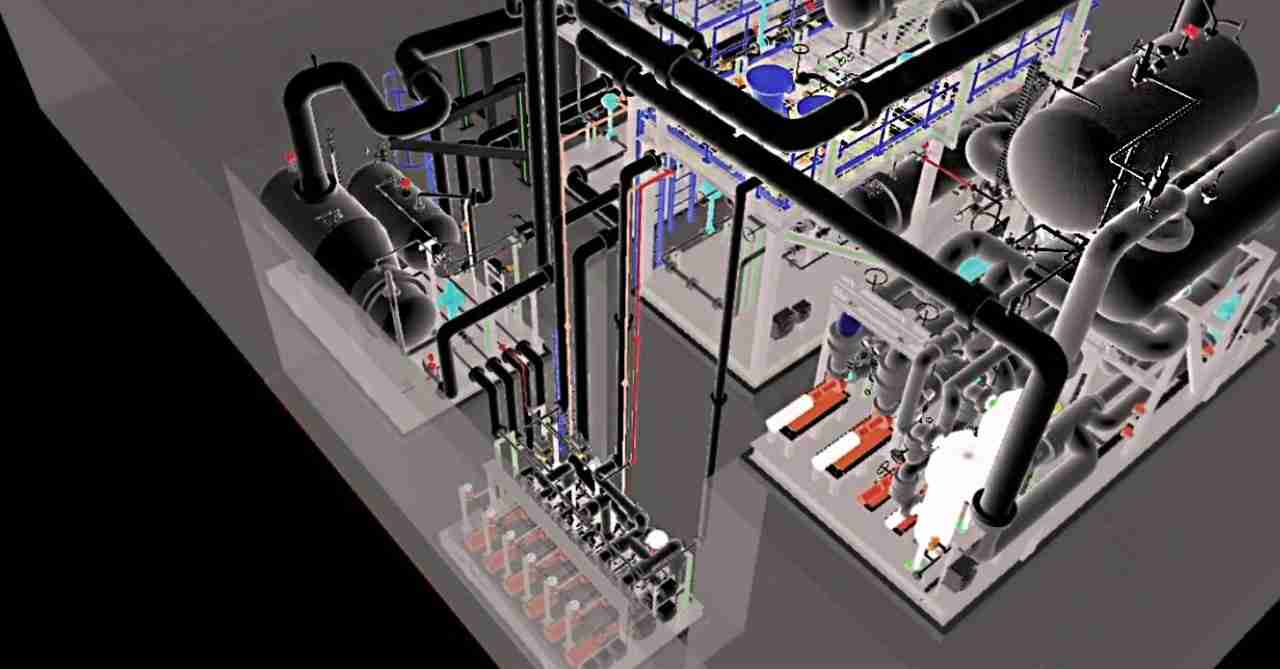

Modular skids

GPE modularizes complex process plants by dividing them into skid assemblies using latest process simulation and 3D...

Read More

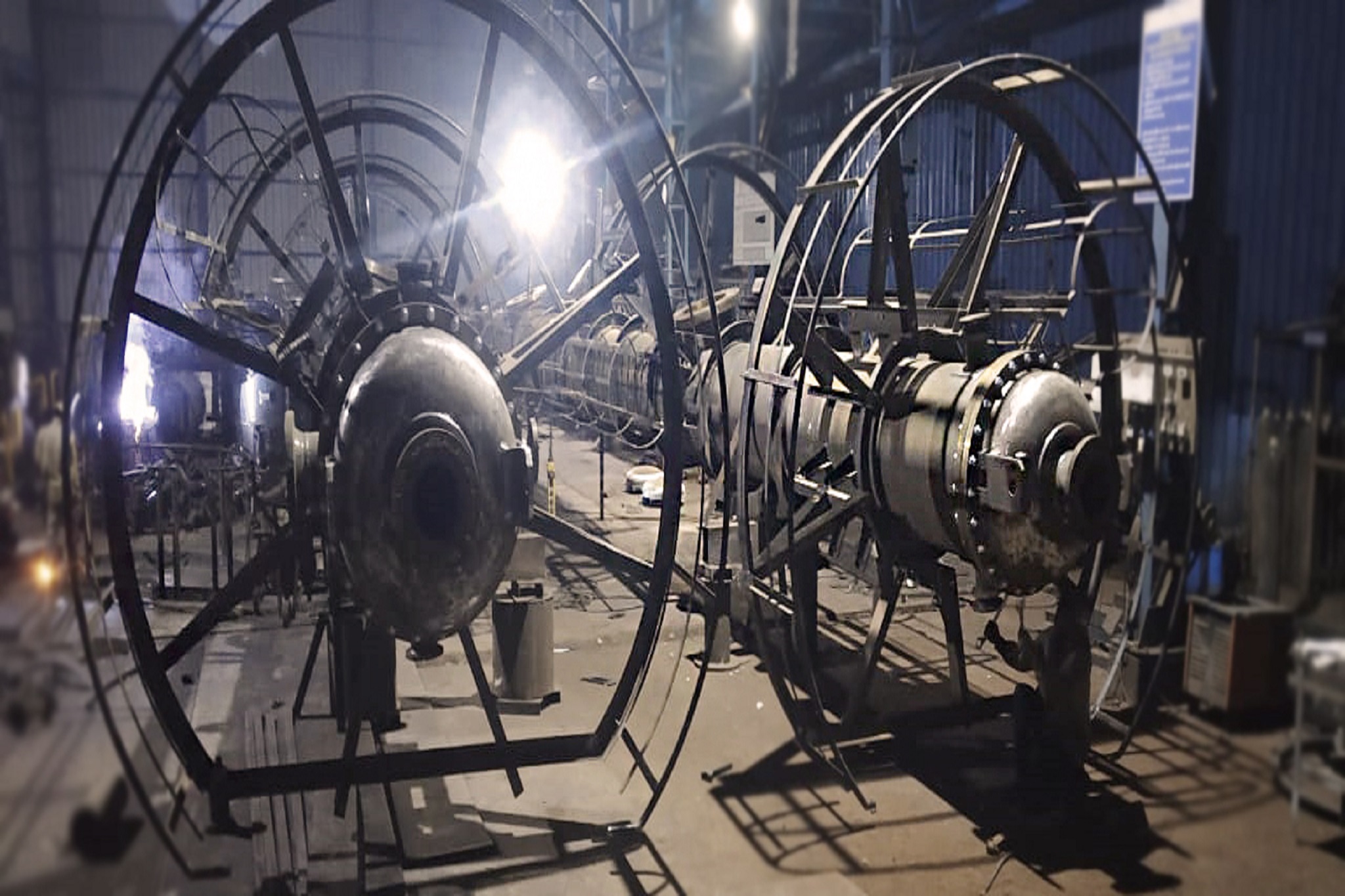

Process equipment

Process equipment supply is GPE’s core competency and we have been engineering and manufacturing...

Read More