Process equipment supply is GPE’s core competency and we have been engineering and manufacturing critical process equipment for more than a decade. We are specialized in manufacturing filters, separators, distillation columns, reactors and various types of critical heat exchangers for a wide range of industries including refineries, upstream oil & gas, petrochemical and fertilizer plants, gas processing stations and power plants.

GPE offers high quality yet cost effective equipment designs as per ASME BPVC Section VIII Division 1 / Division 2, EN 13445, PD 5500 and GOST standards to customers across the world. We deal with materials such as carbon steel, low temperature carbon steel, stainless steel, duplex and superduplex stainless steel, alloy steels, cupro-nickel, hastelloy and admiralty brass. Our quality control department can develop project specific welding procedures for other exotic materials as well as we have built process equipment with design pressures upto 300 bar g, temperatures upto 500 ˚C. for lethal, toxic and hazardous services.

GPE is ASME U Stamp certified organization. We are also regularly exporting equipment in Module-G according to directive 2014/68/EU (CE 0045 marked) to various European countries.

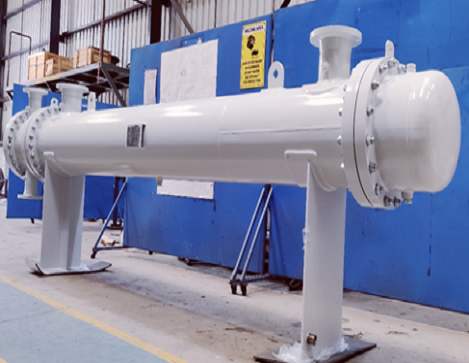

GPE designs and fabricates all types of TEMA shell & tube heat exchangers for upstream oil & gas, refinery, petrochemical, fertilizer, steel and general industry sectors. Our heat exchangers outperform other manufacturers in terms of thermal design, construction quality, ease of maintenance, delivery time and pricing.

For the process design, we have our own licensed simulation software (WINSIM) and for the thermal design, we use HTRI design software. The mechanical calculation is performed by licensed PV Elite. We have handled various gases, liquids and mixed-phase applications for industries like chemical, petrochemical, oil & gas, fertilizer and steel.

We have built hundreds of custom-designed heat exchangers which have been supplied to leading national and international end-users.

We supply separators to leading OEMs and LSTK contractors for use in critical oil & gas applications. In-house process simulation and separator sizing capabilities combined with our world class fabrication facilities ensures superior performance, build quality and on-time delivery.