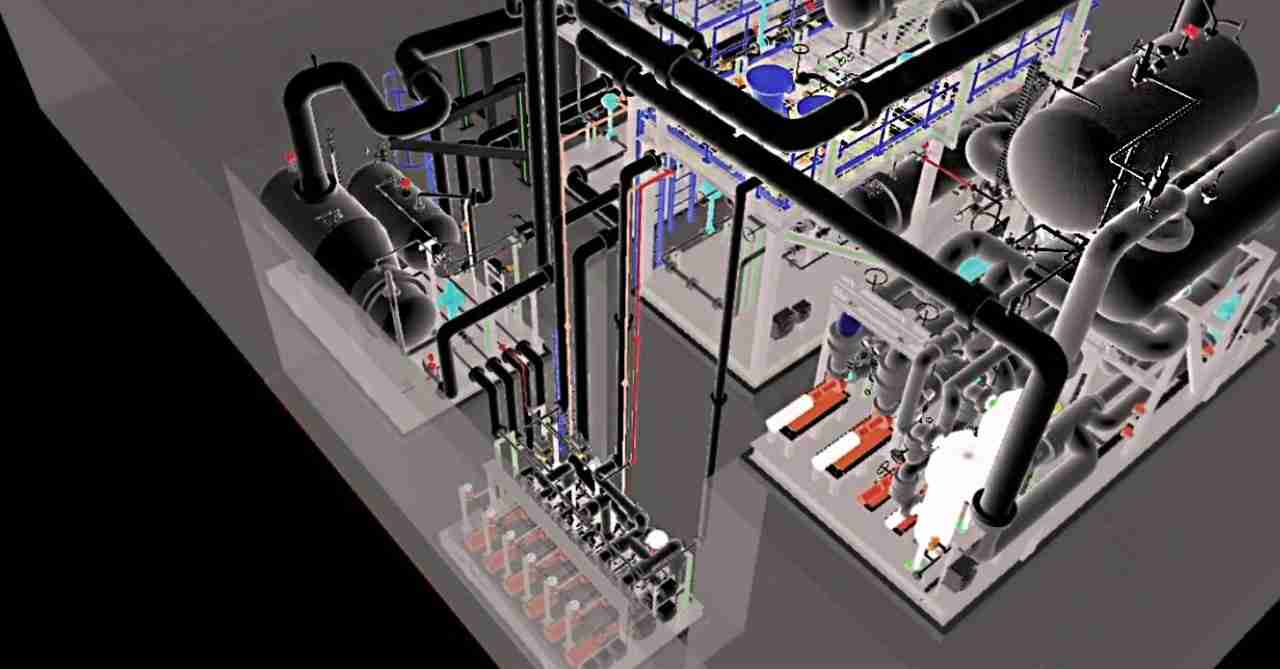

3D models are used by almost all industries nowadays, and in general have 3 stages of review: 30%, 60% and 90%. While the objectives of each stage are broadly known, making a detailed checklist pertaining to one’s product range becomes critical in ensuring the success of a 3D model review. In the oil and gas industry, 3D model reviews between a supplier and a customer, are key to mitigating potential risks and safety hazards at the time of commissioning and operating a plant.

GPE has developed a 3D Model Review Checklist for modular process plants where checkpoints for each stage have been identified. The piping and instrumentation diagram (P&ID) and the available plot area at site form the basis of a 3D model. At the initialization stage, other crucial inputs such as material of construction and thickness of piping and equipment, type of skid structures to be employed, to name a few, are decided upon. This reduces chances of rework to a great extent.

The 30% review stage includes checking of placement of process equipment, process piping, instrumentation items, space allocation for maintenance of major equipment, instrumentation items, among other points.

At the 60% stage, incorporation of utility lines, minor equipment, dimensions of valves and instruments, ladders, walkways, platforms along with many more details is verified. All inputs received at 30% stage should be incorporated at 60% stage.

At the 90% stage, inclusion of all inputs received during the previous stages and last-minute changes by customer is ensured.

Important milestones like releasing of isometric drawings to the production department and transportation outline to the customer are also covered in the checklist.

At GPE, an internal review is carried out at each stage before presenting to the customer. Representatives from all related departments including Process Engineering, E&I, Mechanical Engineering, Production and Project Management attend the internal 3D Model review and discussion points are recorded. Potential roadblocks faced by any of the departments are highlighted which helps in timely resolution of the same. Post the internal review, a meeting with the customer, end-user is organized.

Our 3D Model Review Checklist enabled us to serve customers better. Just as the constantly changing projects, sites, customers and end-users, the 3D Model Review Checklist is constantly changing and developing to capture the smallest of learnings, like deciding the location of nameplate on an equipment, so its view is not obstructed while placement on the skid.